2025 Lib Tech Cold Brew Snowboard

A directional all terrain freeride focused but freestyle ready design that includes a floaty directional nose that reduces fatigue and maximizes fun in pow and crud. Near mid-wide widths and Magne-Traction® serrated edge tech for incredible hold, toe drag free carving and improved float. Built with a long lasting FSC® certified eco core and low maintenance eco sublimated base this board is absolutely brewed to perfection.

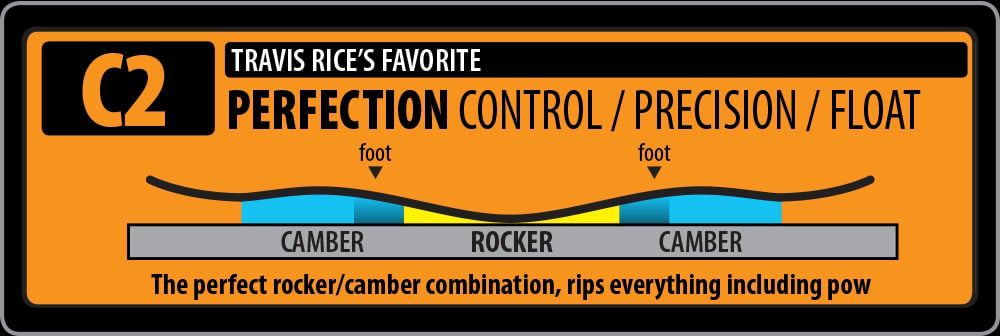

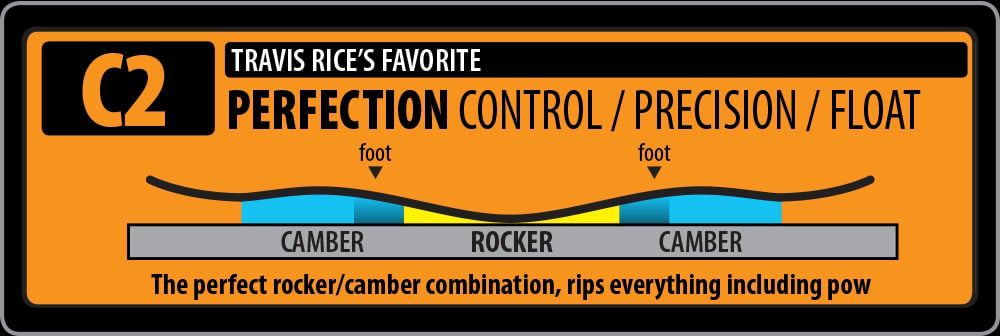

CAMBER PROFILE

- C2 Technology – Lib Tech worked with Travis Rice to develop this perfectly balanced all terrain contour. Mild rocker between your feet with powerful cambers to the tips and tails. Enough power pop and precision to technically hit the biggest wedges, enough float and freedom to rip the gnarliest AK pow lines. Carves the resort, plays in the park, and slays powder.

FLEX

- 6/10 (1=soft, 10=stiff)

- Medium - Stiff Flex – Stout enough to charge your hardest but without excessive harshness.

SHAPE

- Directional

- Low Entry Directional Nose

CORE

- Original Power (OP) Construction – 75% Aspen / 25% Paulownia – Light. Environmentally nice. Strong.

LAMINATES

- Triaxial / Biaxial Fiberglass

SIDEWALLS

- Birch Internal Sidewalls - Extremely rugged high impact 6 ply sidewall reinforcement.

- UHMW Sintered Sidewalls - Strong high impact ultra-high molecular weight polyethylene. Long molecular chains create rugged impact resistance, resilience and a smooth damp ride.

- UHMW Tip/Tail Impact Deflection - Strong high impact ultra-high molecular weight polyethylene. Long molecular chains create unbelievable impact resistance, resilience, a smooth ride and minimize tip and tail spin weight.

BASE

- Eco Sublimated TNT – Fast & low maintenance.

EDGES

- Magne-Traction® – Strategically located edge serrations provide unreal edge hold and control in all conditions. Turns ice into powder.

TOPSHEET

- Eco Sublimated Poly Top - High strength, impact resistant, lightweight dimensionally stable UV and temperature resistant top material decorated using Lib's environmentally friendly eco sublimation process